Medical Device Contract Manufacturing Services and Solutions

As a global contract development and manufacturing organization (CDMO), MGS brings unmatched end-to-end solutions to leading MedTech innovators seeking high-volume, tight tolerance components and medical devices. Our experience in high-value disposables spans a range of markets including ophthalmic, cardiovascular, nephrology, urology and vascular, with expertise in single-use surgical devices.

Leading MedTech and Surgical innovators around the world keep pace with demand and ongoing innovation through collaboration and access to MGS’ end-to-end engineering and manufacturing solutions. Our experts are here to support you throughout the entire process, managing the details of developing and manufacturing high-volume complex components so you can focus on your next great innovations.

Access the Support of a Global Medical Device CDMO

Our global engineering and manufacturing experts collaborate with medical and surgical device manufacturers around the world to produce the medical and surgical device innovations that save lives. Whether launching a new product or transferring your program to drive new efficiencies, our team of experts can help.

Product Design and Development

The MGS team delivers upfront product design and development services that help you bring your product vision to life. Our expertise in R&D, regulatory, quality and project management combines seamlessly with our end-to-end solutions to accelerate your time to market – and your success.

Tooling

Avoid tooling bottlenecks with global capacity and engineering teams close to where you do business. From our innovative Fast-Track Tooling concept through high-cavitation production tooling, we design, build and manage hundreds of high-quality, high-precision injection molds each year.

Automation

Our experts design, build, integrate and validate best-in-class custom automation technologies for assembly, testing and packaging. With solutions ranging from semi-automatic benchtop work stations to integrated press-side automation cells, we work with leading MedTech innovators to deliver custom automation that improves productivity and return on investment (ROI).

High-Volume Production

We combine excellence in engineering and manufacturing to develop complex high-volume components. With more than 250,000-square-feet of Class 7 and 8 cleanroom manufacturing space around the world for injection molding and post-molding services like assembly and packaging, we have the capacity and capabilities to deliver the quality, timeliness and costs you expect.

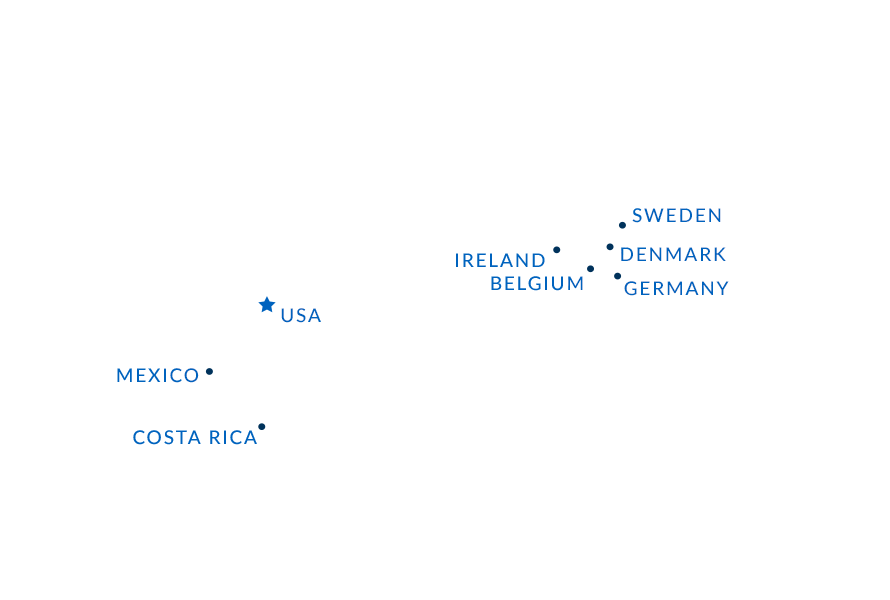

MedTech Components Manufactured Where You Are

Leading MedTech innovators can access MGS’ engineering and manufacturing expertise from any of our 12 global locations. We collaborate across all stages of the engineering and manufacturing process, bringing experts in product development and design, tooling, automation and manufacturing together throughout the process to deliver the best outcomes for you and your end users.

READY TO TALK ABOUT YOUR MEDTECH COMPONENT NEEDS?

We understand MedTech. Across product design, precision tooling, automation and high-volume manufacturing, our experts collaborate with your team to deliver exactly what you need – when you need it.