Custom Automation Manufacturer for Plastic Components

As an early pioneer in multishot molding equipment technologies, including injection units and rotary platens, we apply years of manufacturing technology experience as toolmakers and molders to deliver best-in-class custom automation technologies to Pharma, Diagnostic and MedTech innovators. Using our own manufacturing equipment in-house, alongside innovative technologies from strategic supply chain partners, we know just how to create and design scalable automation solutions that drive ROI for our customers at every stage of the process. This ensures consistent manufacturing efficiency, less manual labor, integration flexibility and cost-effective operations and maintenance.

Scalable Automation Technologies

Cutting-Edge Custom Automation Solutions

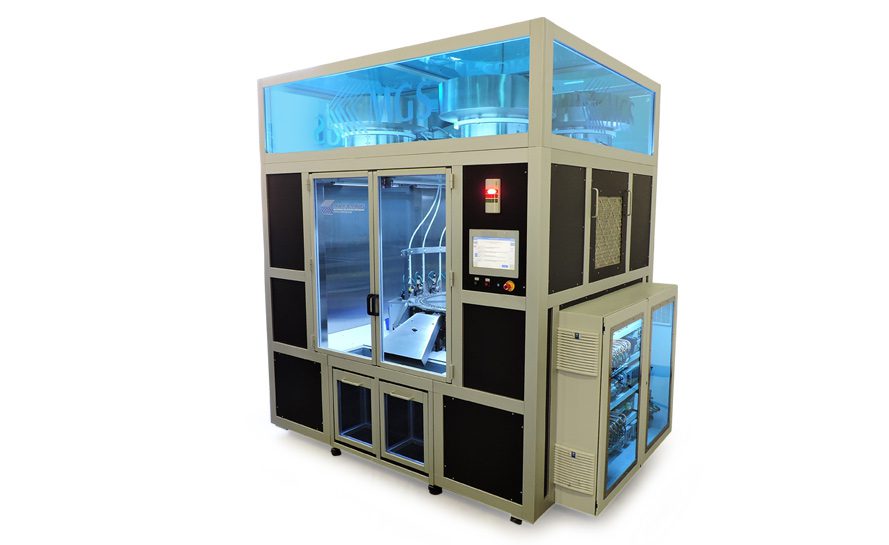

Solutions range from a simple, semi-automatic benchtop workstation to integrated press-side automation cells with fully autonomous downstream assembly/testing, offering independent and automated operations to produce a finished, packaged product.

In-House Solutions

With years of experience in Design for Manufacturability (DFM), we leverage our expertise to excel at:

Mechanical Engineering

Maximizing uptime and effectiveness through the deployment of nearly maintenance-free design, our robust solutions excel at serviceability.

Electrical Engineering

Utilizing state-of-the-art control hardware, our designs minimize control wiring to reduce connection points and ease troubleshooting.

Software Development

More intuitive and easier to use, our front-end software maximizes machine control, reporting and troubleshooting.

All automation equipment is Industry 4.0 (and Euromap 77 & 83) compliant while inherent design and fabrication standards are compliant to Class 8 cleanroom operations.

Quality Control You Can Trust

As the single most important function within any automated process, MGS takes quality seriously, investing in resource training and equipment to perform in-house feasibility studies before committing to process specifications.

Contact Us

Want to learn more about automation can help you reduce costs, increase speed and mitigate risk?