Start Strong, Finish Stronger with Fast-Track Tooling

When it comes to product design and development, you need a partner with the industry and technical expertise to set you up for the greatest probability of success, mitigate risk and drive cost efficiencies. That’s why we leverage our innovative Fast-Track Tooling concept to accelerate timelines while ensuring quality – before you invest in full production tooling.

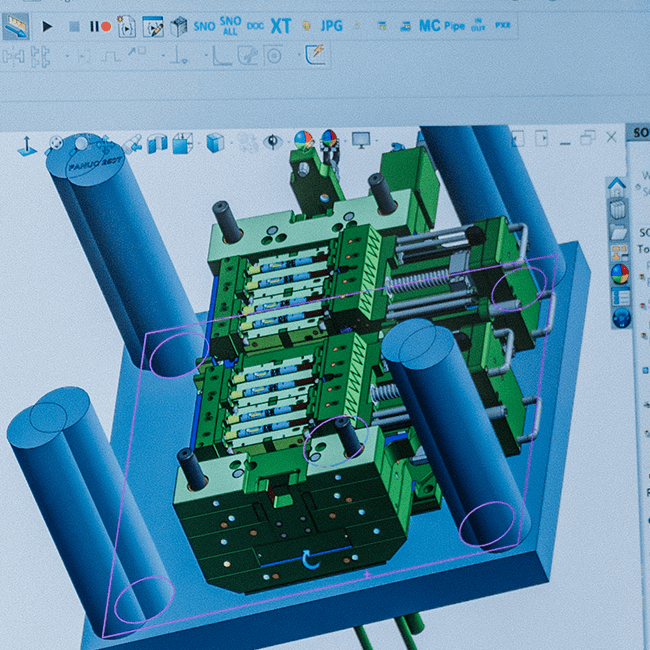

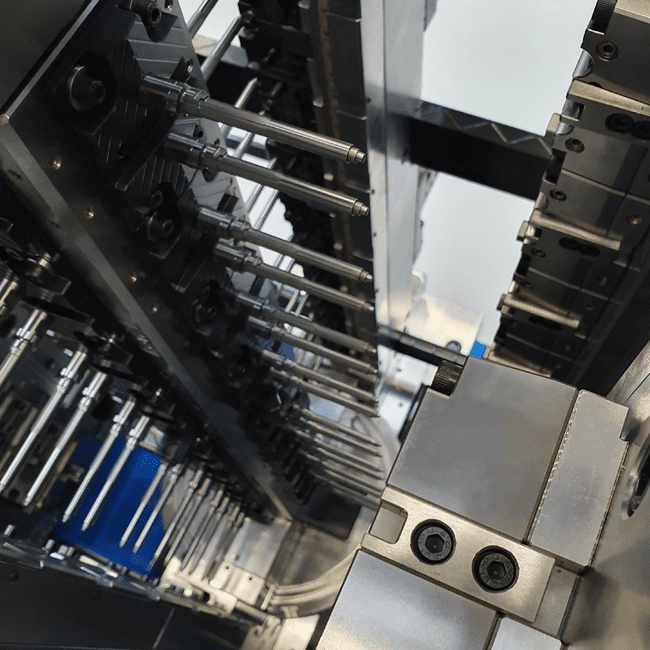

Our multi-step development process delivers pilot mold programs that integrate key learnings from the ESI/DFM process without slowing down your timelines. Our modular Fast-Track Tooling methodology utilizes readily available assets that are customized to your tooling needs. At the end of the process, you walk away with critical knowledge to transition to your production tools and manufacturing processes.

Fast-Track Tooling Concept Mitigates Risks, Accelerates Success

Get to Market Faster With Our Modular Pilot Mold Concept

Our unique Fast-Track Tooling concept provides an early, cost-effective solution to help you learn and capture critical knowledge about your molding process – including real shrinkage, tolerances and part quality – prior to building production molds.

This first-phase production concept accelerates your timeline and efficiency by providing significant opportunities for quality improvement and cost optimization associated with delivering high overall equipment effectiveness (OEE) from your high-volume production molds.

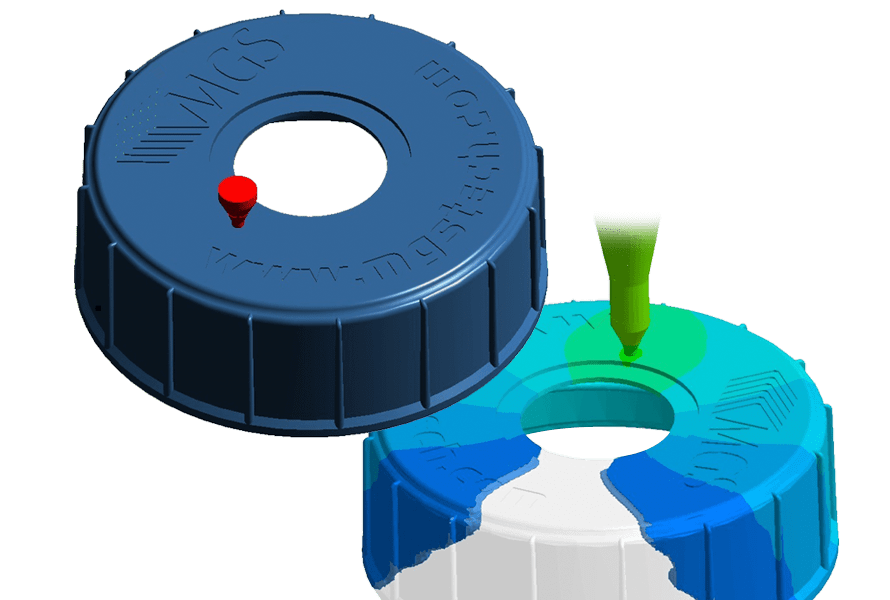

3D Additive Manufacturing Options

As part of our portfolio of Comprehensive Process Simulation Services, we provide prototype part production through an array of 3D Additive Manufacturing options. This is just another example of the level of innovation you can expect from MGS.

Struggling with Tooling Development Timelines?

Contact MGS today to see how our proven processes can get you to market ahead of the competition.