Remote Process Monitoring and Data Management

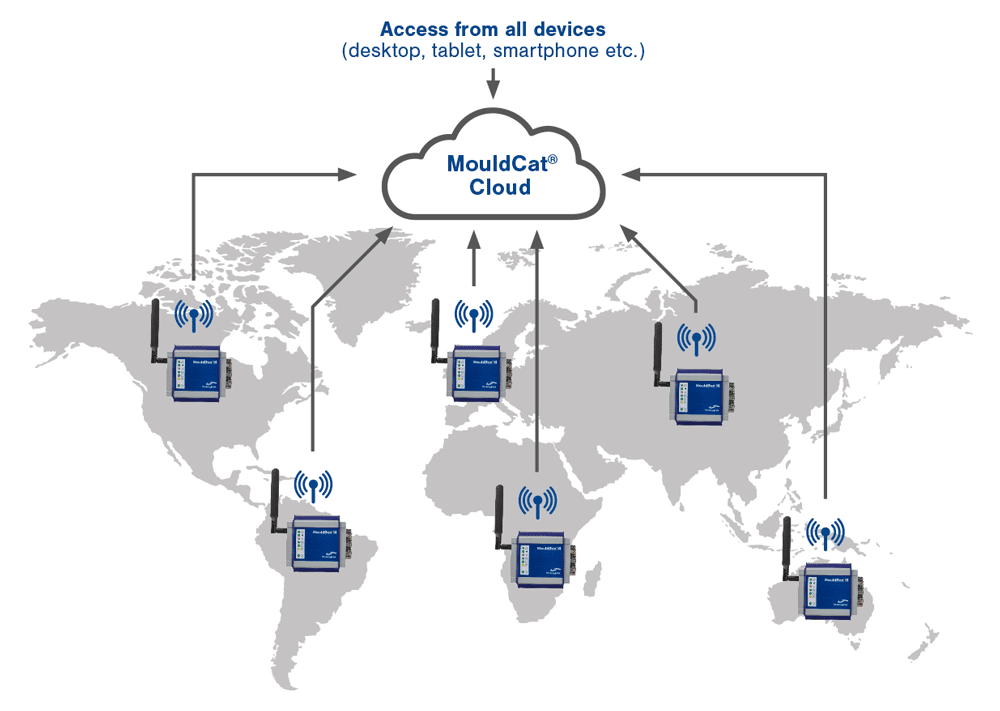

Looking for remote monitoring solutions for your molds that improve productivity, profitability and program quality? Look no further than MGS’ MouldCat® cloud-based software and MouldBox® mold-mounted solutions. With a GSM/NB-IoT or network connection, you can remotely monitor your mold’s performance, process, location changes, quality and need for service. Collect data that accelerates your ability to maximize uptime while avoiding costly delays and repairs throughout the life of your tool.

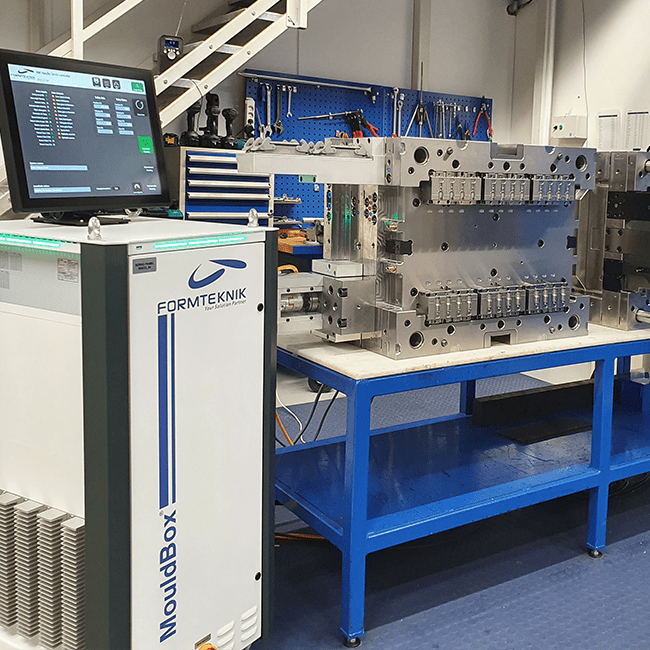

Mouldbox®

MouldBox®, also created by Formteknik, offers a standardized, modular solution from cloud-based mold monitoring to servo technology and hot runner control. A GSM or network connection allows external, worldwide monitoring of mold performance, process quality and service needs. Each MouldBox® continuously records mold data and sends it to the MouldCat® Cloud, giving you global access. Data can be accessed and evaluated by operators at anytime, anywhere. This includes:

- Mold performance monitoring.

- Monitoring of process or location changes.

- Indications for necessary tool maintenance.

- Internal reminders for service.

- Online support in error diagnostics.

Key MouldBox® features include:

- Reliable preventative mold maintenance processes.

- Integrated process monitoring.

- Recording of cycle time and number of cycles.

- Recording of up to four temperatures.

- Data buffering on SD card.

- Definition of limit values/alarms.

- Interface to structure-borne sound sensors.

- WLAN interface.

Mouldbox® Benefits

Easy to Install

Full-Servo Control

Precise Hot Runner Control

MouldCat®

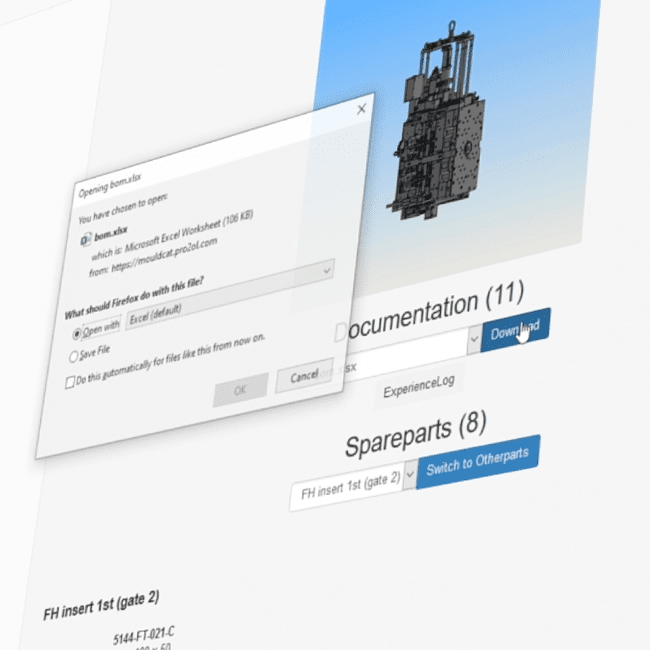

Developed by Formteknik, MouldCat® was uniquely created to house all critical project documentation – and keep it up to date. This web-based, easy-to-use portal drives simplicity for your mold management while also keeping your tools performing at their highest levels.

Important MouldCat® features include:

- Protected customer login.

- Complete mold documentation.

- User requirement specifications (URS).

- Measurement reports.

- All connection and wiring diagrams.

- All sampling and approval protocols.

- All spare parts accessible 24/7 via online shop.

- Defined process data.

- Always accessible and up-to-date.

MouldCat® offers a user-friendly interface that allows you to display your MouldBox®-connected tools on a zoomable map. The platform enables you to define alarm limits individually, configure service intervals and receive reminders via push notification. This platform also enables you to monitor total number of cycles, cycle time development, online updates, user-level-management and more.

Struggling with Tooling Development Timelines?

Contact MGS today to see how our proven processes can get you to market ahead of the competition.